WELCOME TO BENGS MODELLBAU

New Artikel at Bengs Modellbau

About us

The company Bengs Modellbau was founded in 2003. We started out exclusively as a supplier of parts for steam model building. After some time, the first material kit for a steam engine was added. The area of kits developed so well that in 2004, in addition to steam engines, we also produced the first flame eater model, the Flame Eater “Nick” were able to offer. The flame eater “Nick” is still very popular with model makers in Germany and abroad. To mark this occasion, an enlarged model of this popular flame eater was available from the end of 2005. To round off the range of hot air engines, the first Stirling engine followed in 2005. With the material kit for the Stirling engine "Laura" you can build a small Stirling engine yourself. This was followed by model building material sets for steam engines, Stirling engines and flame eaters. Particularly popular is the model of the steam engine "Donatus" it is a standing trestle. Steam engine with centrifugal governor . In order to bring beginners closer to technical model making, we have the material kit for the & nbsp; Steam engine “Danni” published. A small horizontal steam engine with slide control. For the tenth anniversary of Beng's model making, we have released a horizontal Stirling engine as a material kit. The Laura Stirling engine is a very powerful model Stirling engine that can run for 10 hours on one tank full.

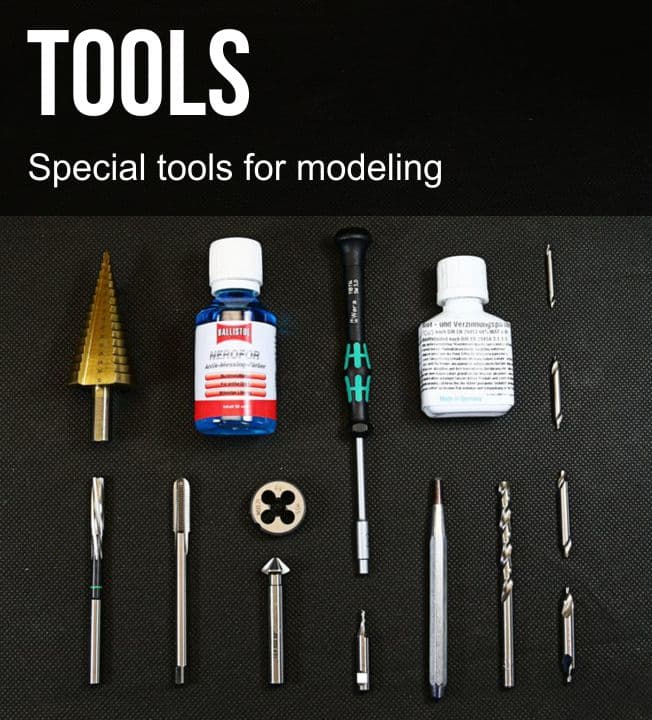

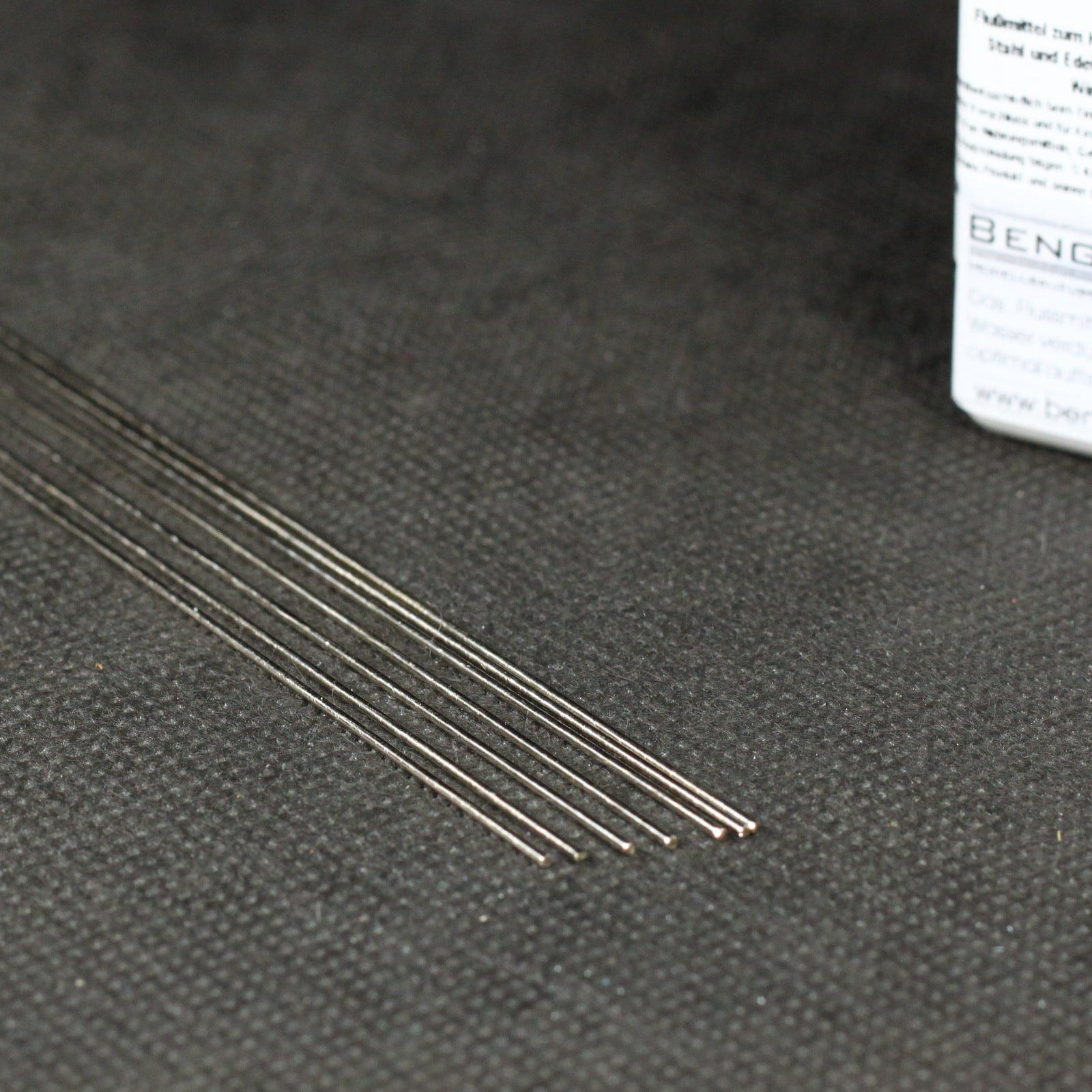

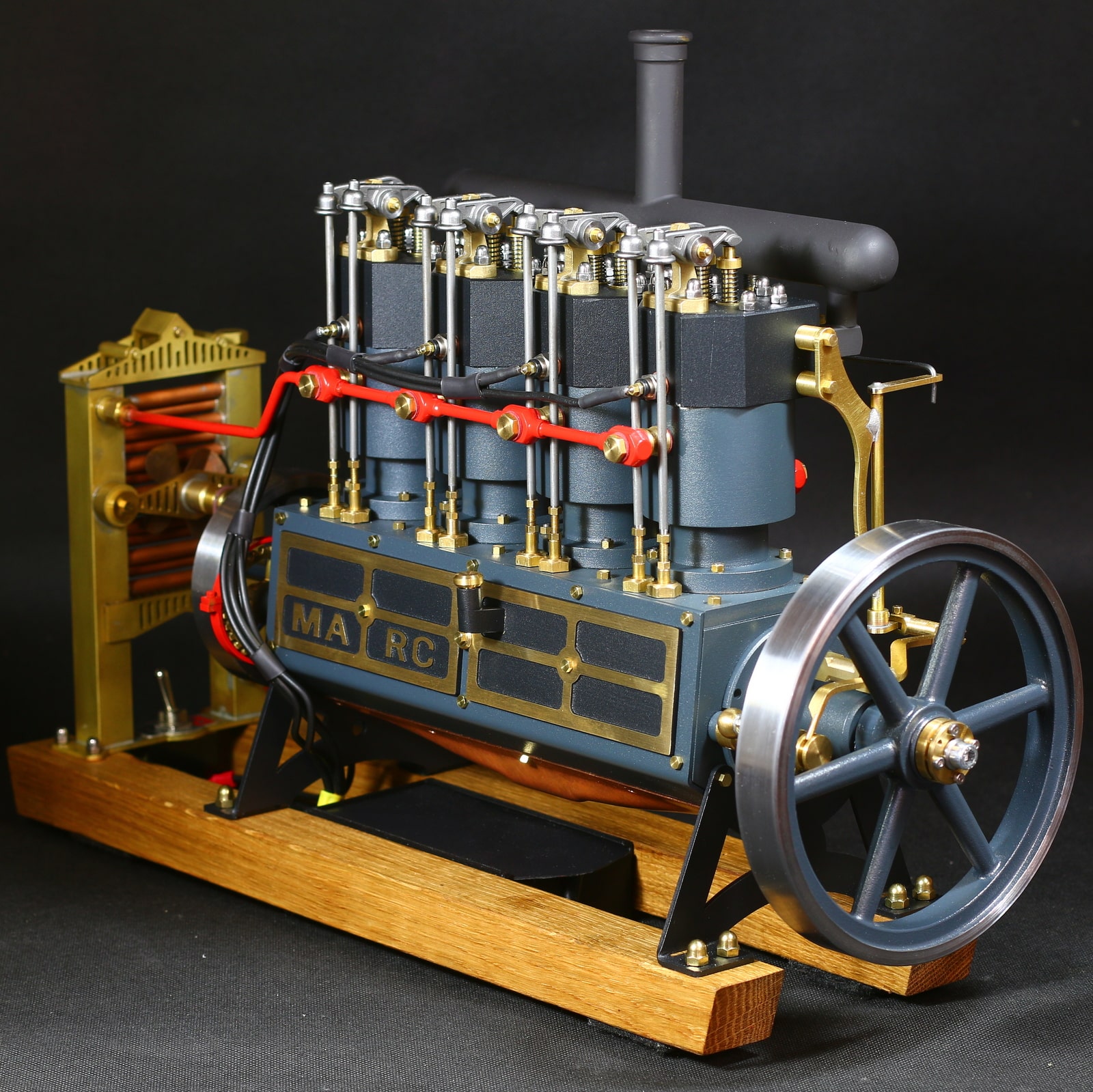

From the end of 2014 we will present you the first kit with which you can build a functioning model combustion engine in model size, the 4-stroke Combustion engine “Karl”. In addition to the constantly expanding range of kits, we have also continually expanded our range of tools and materials for the model maker. We now offer both copper pipes, brass pipes, brass semi-finished products, screws and also O-rings in our model making& nbsp; Shop on. When it comes to tools, we limit our offerings exclusively to tools that we also use in our model workshop. Many of the tools needed to build a steam engine, Stirling engine or flame eater cannot be found in hardware stores, which is why we have a wide range of tools for technical model building. We ourselves have been using the taps, reamers and silver solder we offer for many years.

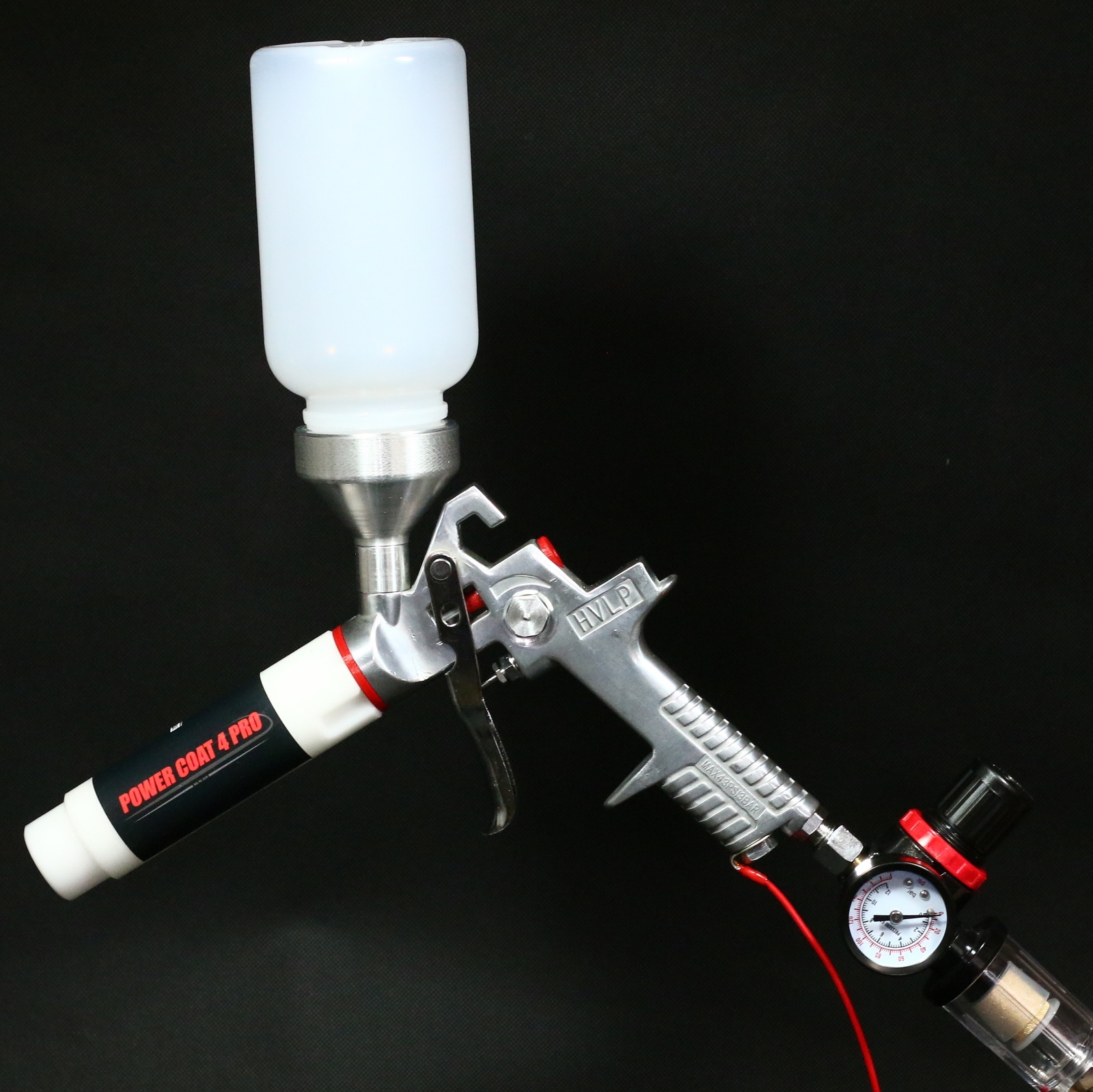

Now not only many model makers appreciate our model building tools, but also many Customers from other industries. We also offer you an extensive selection of articles on the subject of powder coating. From us you get a simple powder gun or thePower Coat 4 PRO powder coating device. Of course, you can order the required coating powder, high-temperature adhesive tape or dust masks from us. We ourselves use both powder coating guns in our workshop and can recommend them to both model builders and tradespeople.

Purchased frequently

Average rating of 5 out of 5 stars

Our offer

- Material kits: Pre-milled material kits for flame eaters (hot air engines), Stirling engines, steam engines, burners and combustion engines.

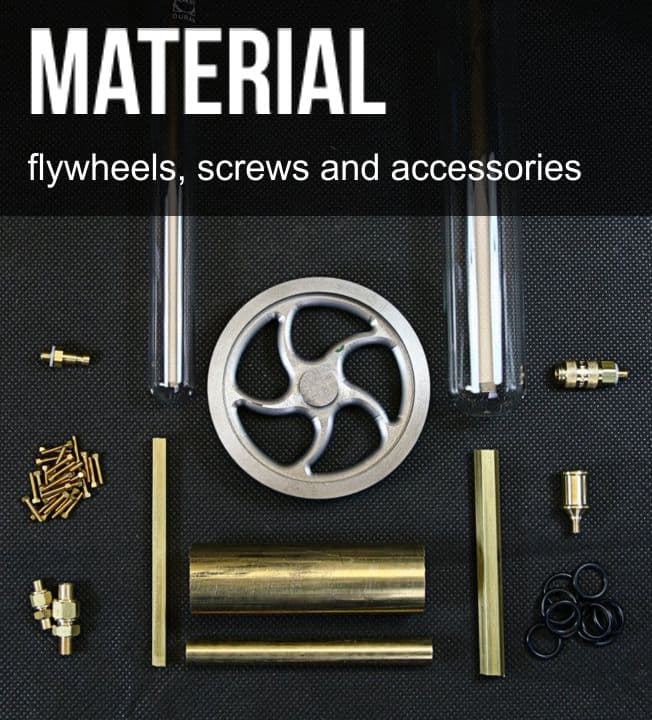

- Model building accessories : Extensive range of parts for steam model making and functional model making.

- Tools: An attractive selection of high-quality tools, soldering accessories, dies and taps for technical model making.

- Model making material: The complete range on sealing elements, flywheels, screws and semi-finished products.

- Powder coating: Depending on your needs, you can get 2 different powder coating guns from us for powder coating yourself.