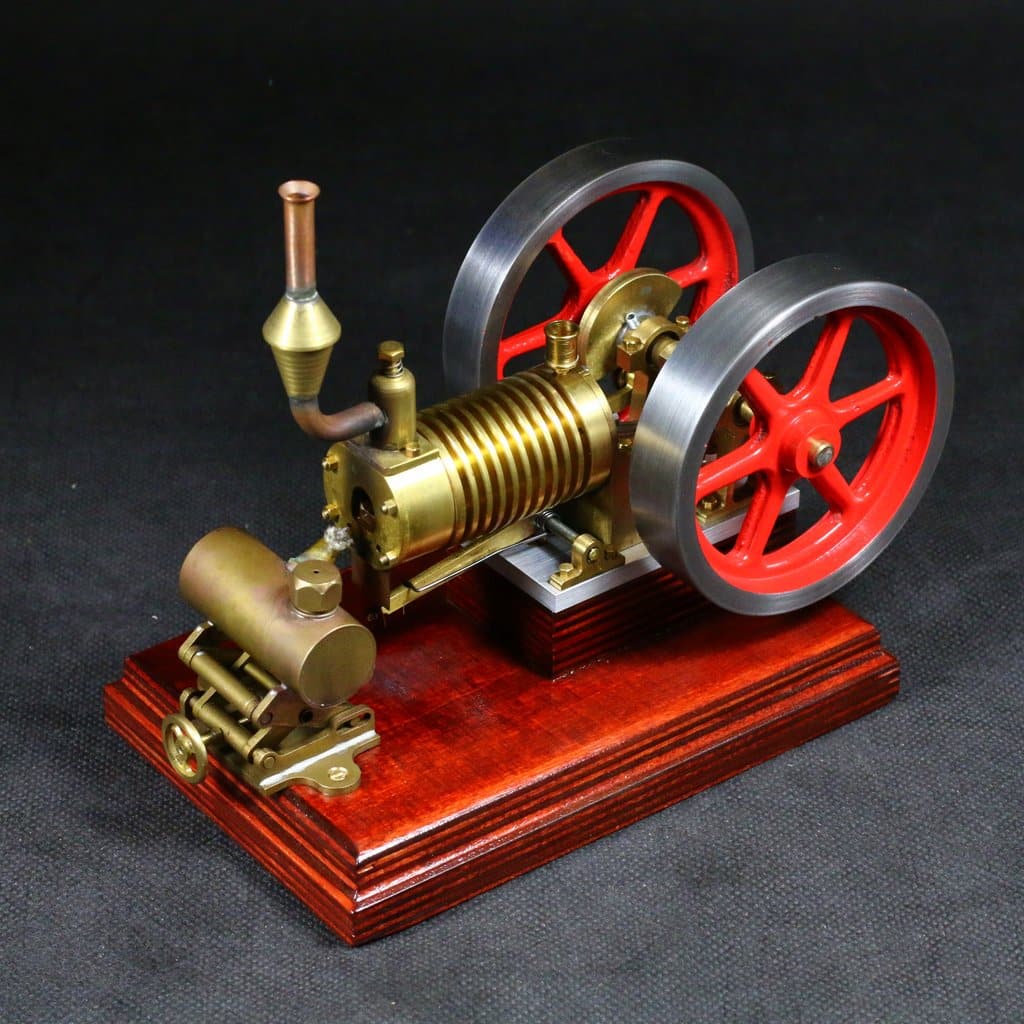

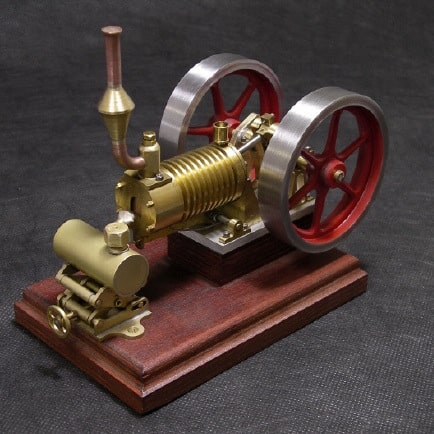

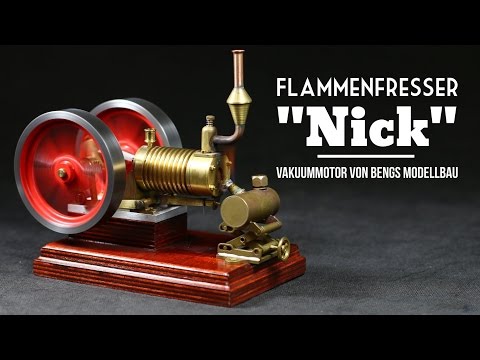

Flame licker Nick

Product information "Flame licker Nick"

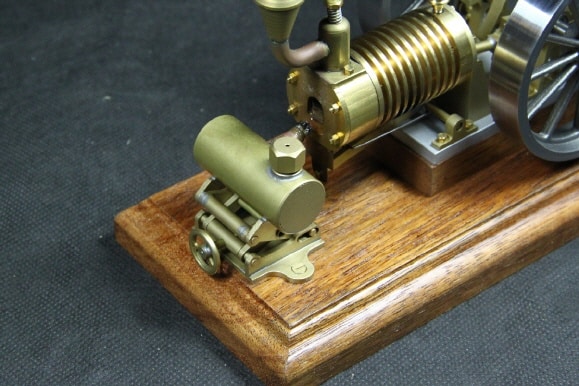

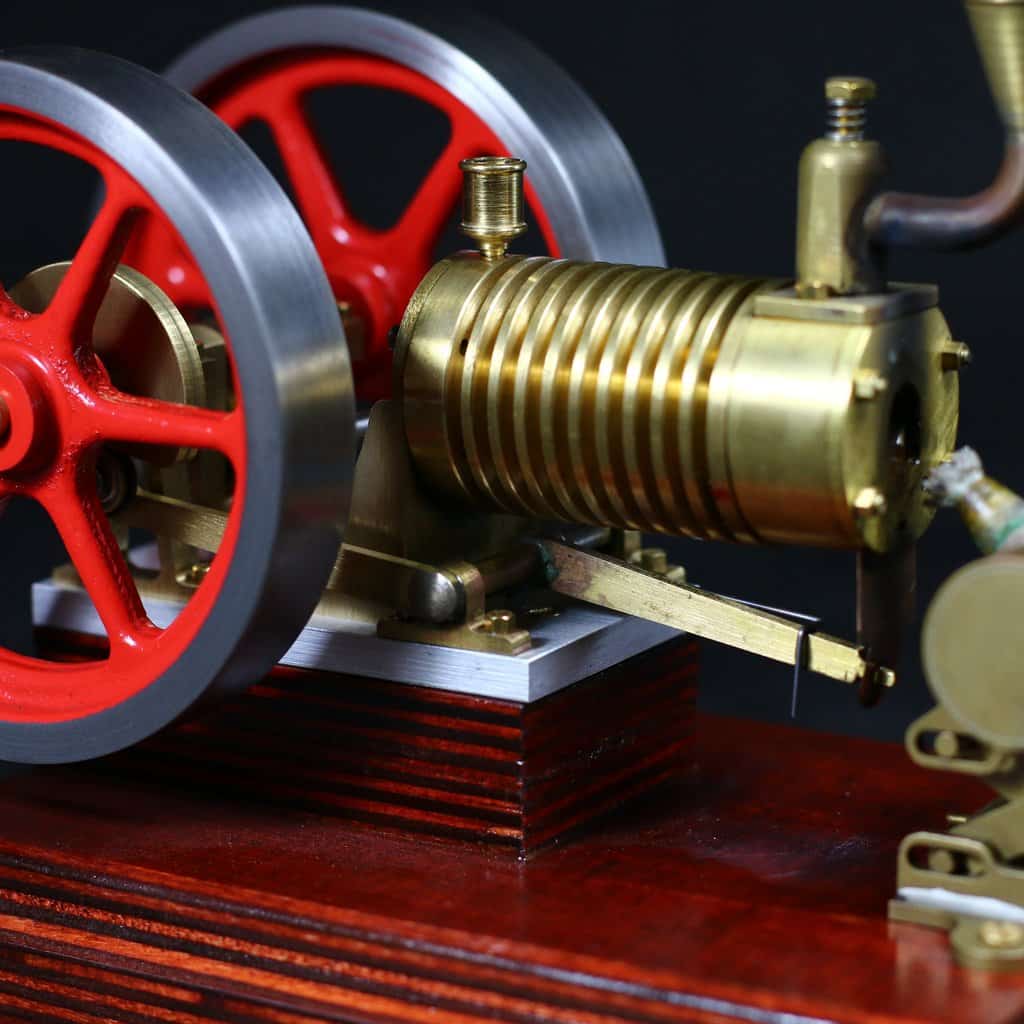

The vacuum motor or flame eater 'Nick' is mostly made of brass. The flywheels are made of cast steel. 'Nick' is mounted on a varnished wooden panel. The crankshaft has ball bearings. It runs at around 200-400 rpm. The burner is height adjustable so that the speed can be regulated using the handwheel. The flame eater needs a few minutes to reach operating temperature. It can then be started with a gentle push on the flywheel. Once it is in operation, it runs for many minutes with a beautiful sound.

All milled parts have already been machined and some still need to be drilled. The materials, screws, ball bearings and spring elements required to build the flame eater and burner are included in the kit. To build the flame eater you need a small lathe, a small drill, as well as a gas burner for soldering larger parts and a burner for brazing small parts. Otherwise, hand tools, which should be in every “steam engine workshop”, are necessary (tap M2, M3, M8x0.75, cutting die M3 and M8x0.75, reamer 3H7, 4H7, 6H7, files, drill set).

Would you like to see in advance what work is still being carried out? Then take a look at the construction report from the flame eater “Nick” in our Bengs model building magazine. Here you will find many pictures and small explanatory texts about what needs to be taken into account during construction. This construction report can certainly provide you with additional support during the construction phase.

Dimensions of the “Nick” flame eater with base plate

- Length: 170mm

- Width: 100mm

- Height: 110mm

- Flywheel D.: 80mm

- Piston D.: 16mm

- Stroke: 26mm

The Flame Eater Nick material kit includes:

- Finished milled parts

- Raw material for the turned parts

- Two 80mm flywheels made of cast steel

- Milled wooden base plate made of oak

- All required screws, nuts, ball bearings and spring elements

- Construction plan flame eater drawings (9 sheets) and construction instructions (6 sheets)

- Construction plan burner drawings (3 sheets) and construction instructions (2 sheets)

- Kit for the burner, height adjustable

If you ever need a spare part, you are of course welcome to order it from us.

Hersteller

Bengs ModellbauIm Kirchfelde 6

31675 Bückeburg

info@bengs-modellbau.de

Verantwortliche Person

Patrick BengsBengs Modellbau

Im Kirchfelde 6

31675 Bückeburg

info@bengs-modellbau.de

Login