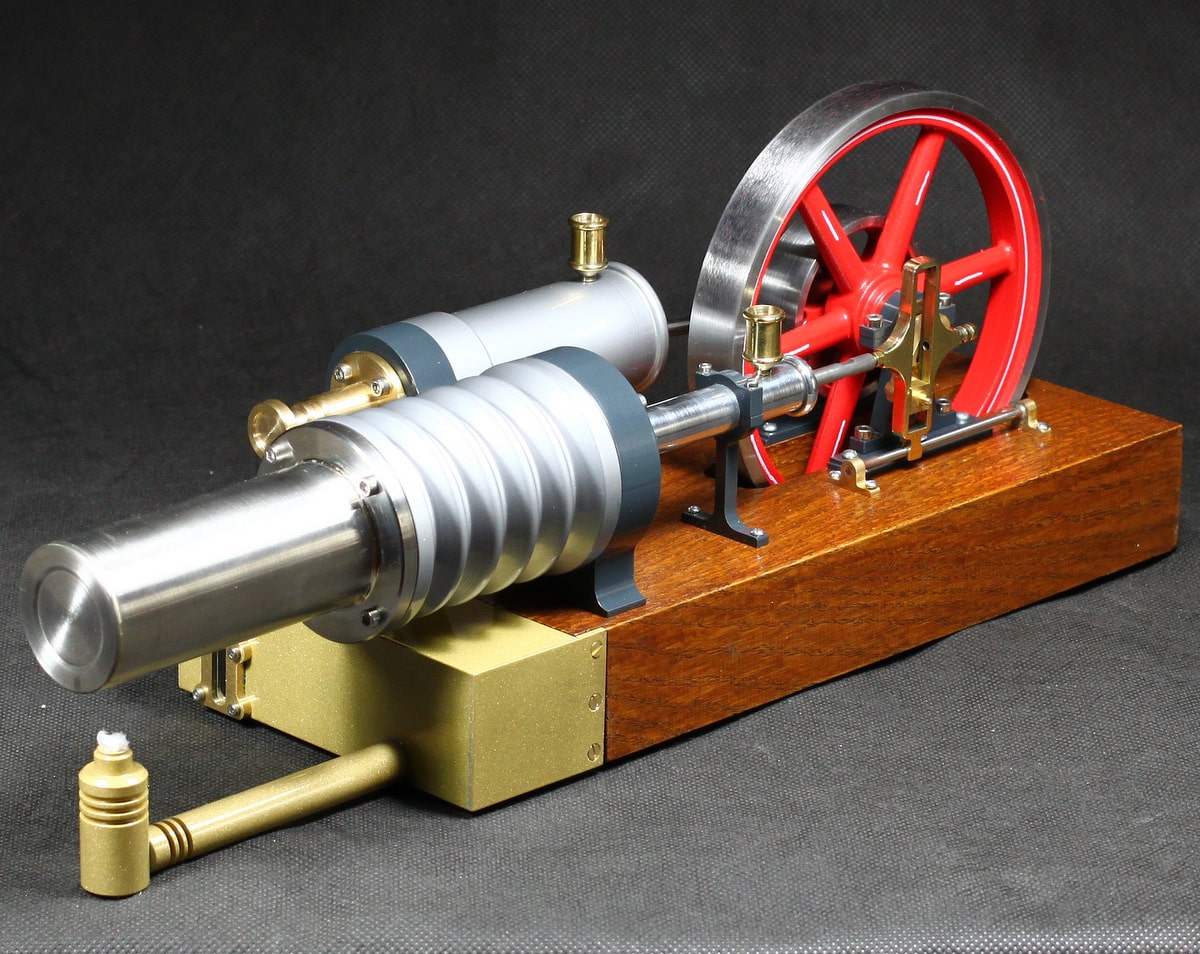

Stirling engine Rainer with centrifugal governor material kit

Product information "Stirling engine Rainer with centrifugal governor material kit"

The original

The model Stirling engine

Speed control via centrifugal governor

Dimensions of the model Stirling engine

- Base plate: 255mm x 120mm

- Flywheel: 140mm

- Pulley: 48mm

- Total height: 210mm

- Working piston: 28mm

- Displacer piston: 25mm

- Length overall: 285mm

- Wooden base plate

- Finished milled parts

- Brass, steel, stainless steel and silver steel

- Raw material for the turned parts

- Cylinder sleeve made of precision tube

- flywheel

- All required screws, nuts, gaskets, grub screws and wick

- Construction plan model Stirling "Rainer" drawings (14 sheets) and construction instructions (9 sheets)

Hersteller

Bengs ModellbauIm Kirchfelde 6

31675 Bückeburg

info@bengs-modellbau.de

Verantwortliche Person

Patrick BengsBengs Modellbau

Im Kirchfelde 6

31675 Bückeburg

info@bengs-modellbau.de

Login

2 reviews

13 August 2024 16:44

Toller Materialbausatz

Gut durchdacht und auch auf einer kleinen Drehbank (Sieg C2) machbar. Wenn ich den Motor nochmal bauen sollte, würde ich ein paar Kleinigkeiten anders machen: - Die Weichlötungen würde ich durch Verklebungen mit Hochtemperatur-Epoxidharz ersetzen, ist einfacher in der Handhabung. - Im Verdrängerkolben eine kleine Druckausgleichsbohrung (1,5mm) vorne, ich habe sie nachträglich angebracht - Die Verdrängerwelle würde ich aus Sechskant- oder auch Vierkant-Material herstellen, man erspart sich die Planfräsung für die Gabel des Verdrängerkolbens. - Gabel und Abstandshalter für den Verdrängerkolben würde ich nicht mit Gewinde versehen, sondern mit Zapfen und Bohrung, die dann verklebt oder auch verlötet werden, ist einfacher zu justieren.

6 March 2024 10:49

Gratuliere, wunderschönes Modell, kommt auf meine ToDo-Liste. HaJo

Gratuliere, wunderschönes Modell, kommt auf meine ToDo-Liste. HaJo