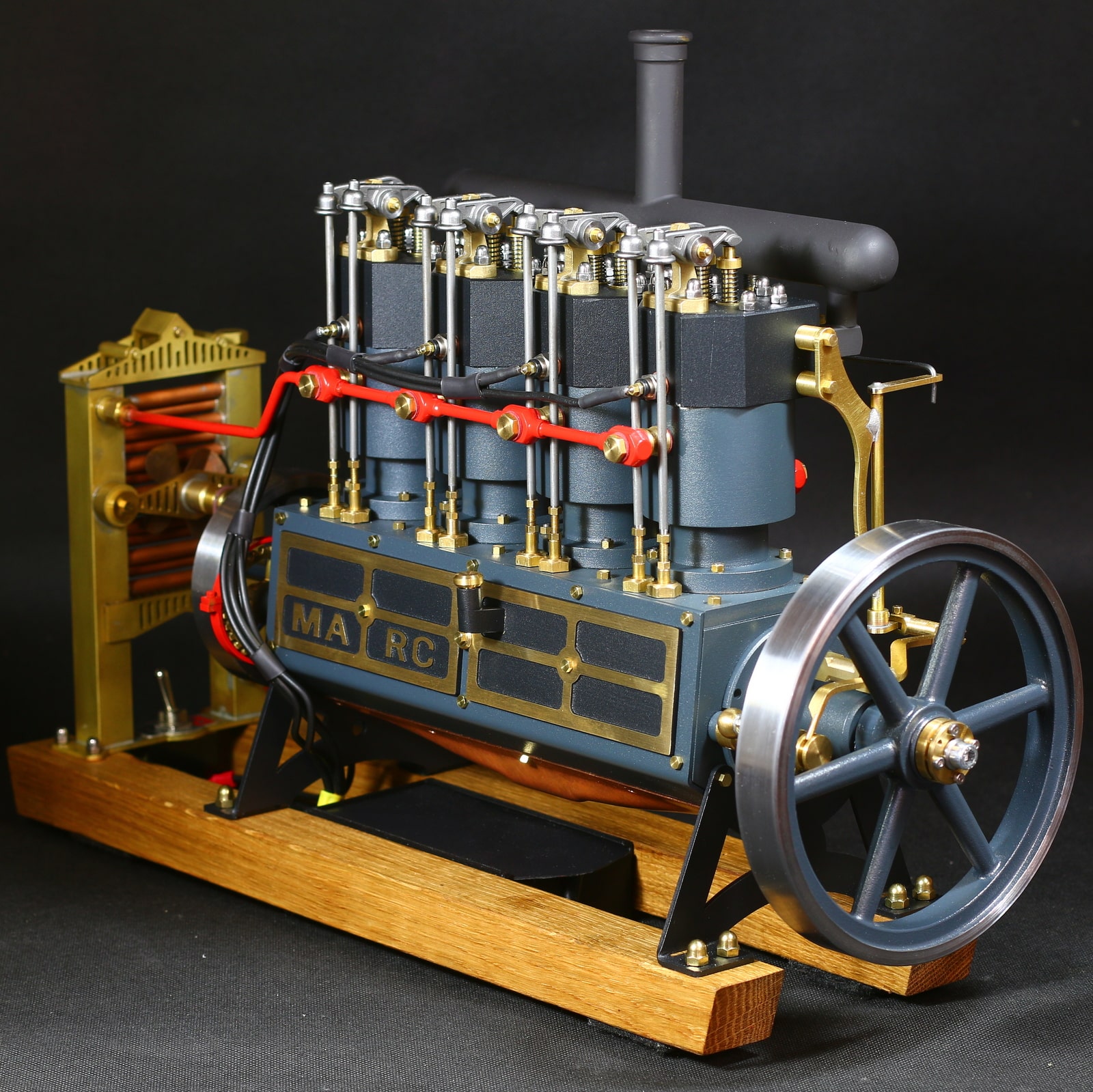

4 cylinder internal combustion engine Marc material kit

Product information "4 cylinder internal combustion engine Marc material kit"

The 4-cylinder in-line engine "Marc" is based on a historical model. The model was a four-cylinder in-line engine that was manufactured by the American company Holt at the beginning of the 20th century. This engine was mainly used in bulldozers and tracked tractors. This engine was available in 2, 4 and 6 cylinder versions. In 1925, the Holt company became the Caterpillar company, which still exists today. The engine does not consist of a cast engine block, as was usual later, but still has individual cylinders. This design is visually very appealing and makes it possible to offer the engine as a material kit.

- Speed control via centrifugal governor

- Carburetor with adjustable throttle valve

- Cooling circuit with cooling water pump

- Cooler with fan

With the 4-cylinder in-line engine "Marc" material kit, you can build a fully functional combustion engine yourself. The material kit contains all the necessary parts including the ignition. The engine has a functioning speed control using a centrifugal governor. A cooling water pump pumps water through a radiator, where the cooling water is cooled down by the fan and then flows back into the cylinder jacket. The engine is equipped with glow plugs. The glow plugs come with four Batteries operated. All components for producing the ignition are included (batteries are not included).

Dimensions of the model combustion engine 'Marc':

- Height with wooden base: 310mm

- Length: 450mm

- Width: 180mm

- Piston diameter: 23mm

- Flywheel D.: 1x140mm 1x80mm

- Speed speed: 200-1000 rpm

- Weight: 9.1kg

The engine stands on two oak runners. The engine block is screwed together from milled parts. The base plate for the cylinders is made of steel, the bearing blocks that hold the crankshaft are made of aluminum. This unit is then provided with finished lasered and folded sheets. The cylinder sleeves are made of brass, the inside diameter no longer needs to be machined. The cylinder head and cylinder are included as material sections and must be machined on the lathe. The remaining components are mainly made of brass. The crankshaft is made from individual segments. No milling machine is required to produce the crankshaft either. It can be built entirely on the lathe. Further information can be found in our build report for the four-cylinder engine. The two flywheels are available in the quality we know. Both flywheels are made of cast steel.

The speed of this model is controlled via the carburettor. You can regulate the amount of air supplied. The carburettor is connected to a centrifugal governor via a linkage. This means you can set the engine to a desired speed, which is then maintained under load using the centrifugal governor.

Here you will find an extensive construction report of the four-cylinder internal combustion engine Marc< /a> with lots of pictures and additional texts.

Here you will find extensive assembly instructions for the combustion engine On the page you can see how you have to put all the manufactured parts together.

Here you will find extensive instructions for the Commissioning and operation of the four-cylinder engine Marc

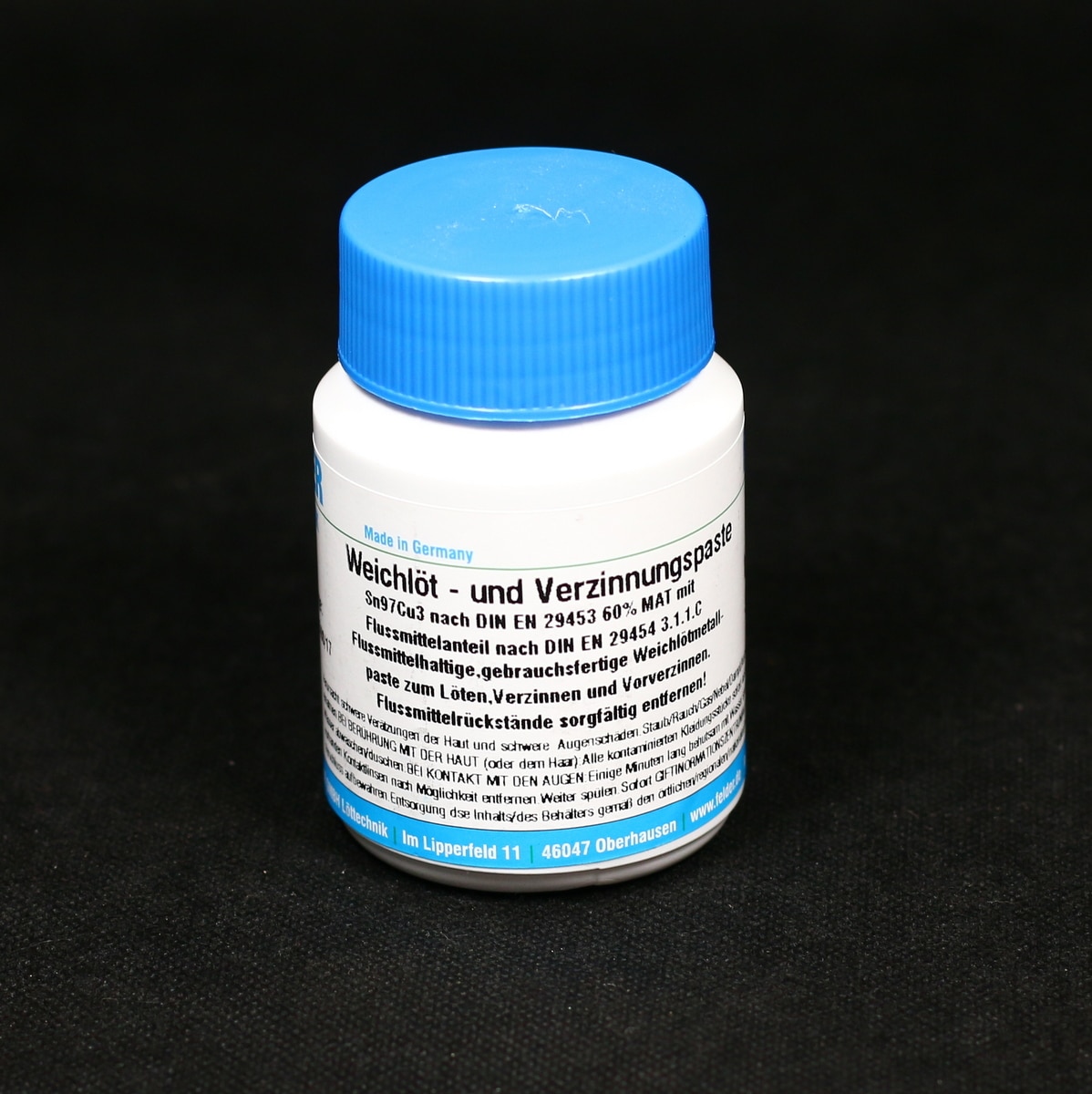

All materials required to build the internal combustion engine "Marc" screws, nuts, springs and ignition parts are included in the kit. All milled parts are prepared so that they only need to be deburred and possibly drilled. To build the vertical stationary motor, a lathe, a drill and a gas burner for soft soldering are required. The following hand tools are also required (tap M2, M3, M4, M5, 6x0.75, M8x0.75, M10x1 die M2, M3, M5, M6x0.75, M8x0.75, M10x1 reamer 4H7 6H7, 8H7, 10H7) Files and a drill set are necessary. All you need to wire the ignition is a pair of side cutters, wire strippers and a soldering iron.

If you would like to find out in advance what steps you will take to make this internal combustion engine

have to be carried out, take a look at the construction report of the 4 cylinder combustion engine "Marc" material kit in our Bengs model building magazine. On this page you can see the illustrated report on how the stationary motor material set is processed.The scope of delivery includes:

- finished CNC milled milled parts

- Raw material for the turned parts

- Rough casting part for the flywheels

- 2 runners made of oak wood

- All required screws, nuts, gears and seals

- Drawings of the internal combustion engine "Marc" (36 sheets) and construction instructions (8 sheets)

- Glow plugs, cables, cable clamps, battery compartment for the ignition

- Laser parts for stands and fairings

Hersteller

Bengs ModellbauIm Kirchfelde 6

31675 Bückeburg

info@bengs-modellbau.de

Verantwortliche Person

Patrick BengsBengs Modellbau

Im Kirchfelde 6

31675 Bückeburg

info@bengs-modellbau.de

0 of 0 reviews

Average rating of 0 out of 5 stars

Login

Kunden Kauften auch

Content: 0.1 Kilogramm (€102.00* / 1 Kilogramm)