Belt sander BS1500 welding kit

Product information "Belt sander BS1500 welding kit"

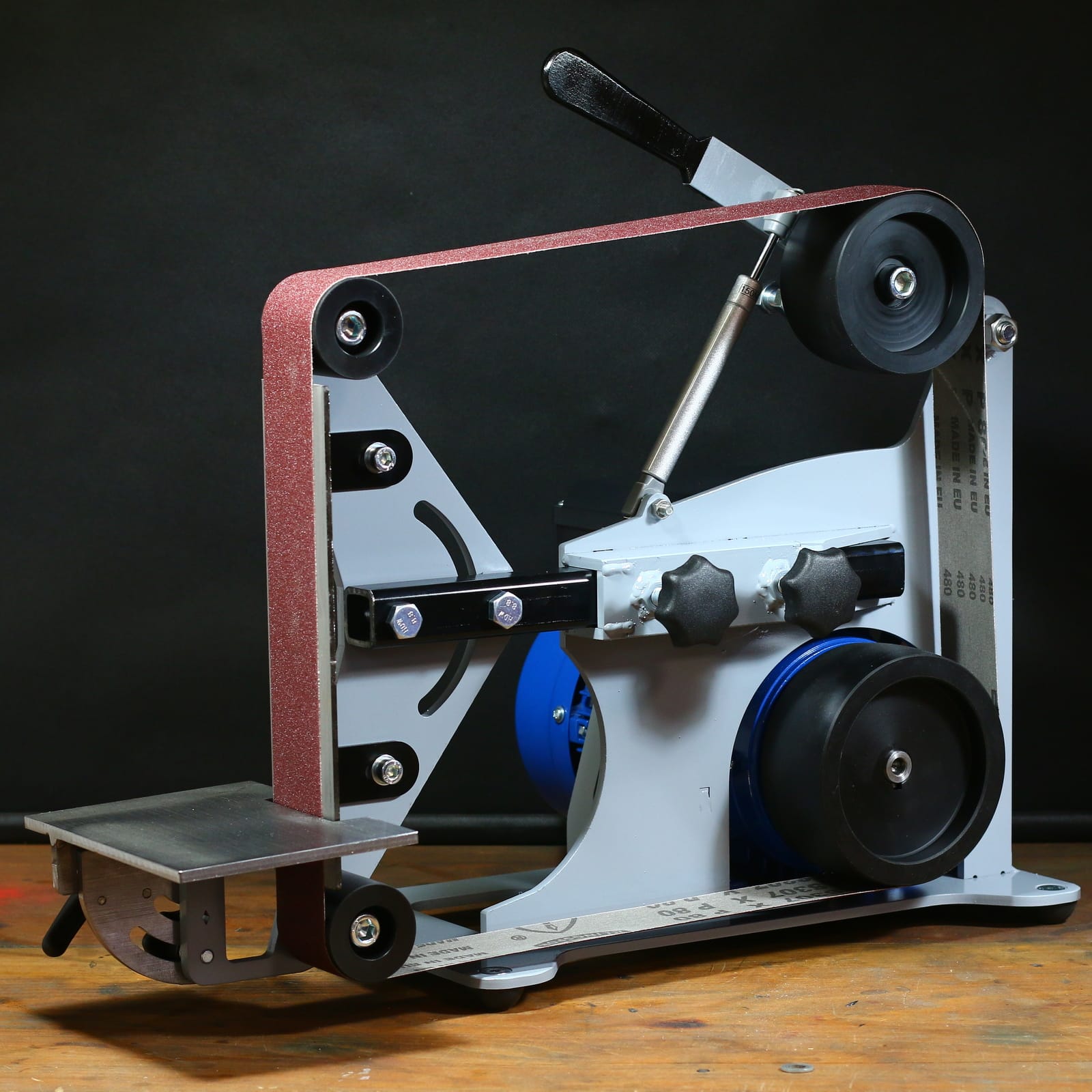

Belt sander BS1500 welding kit

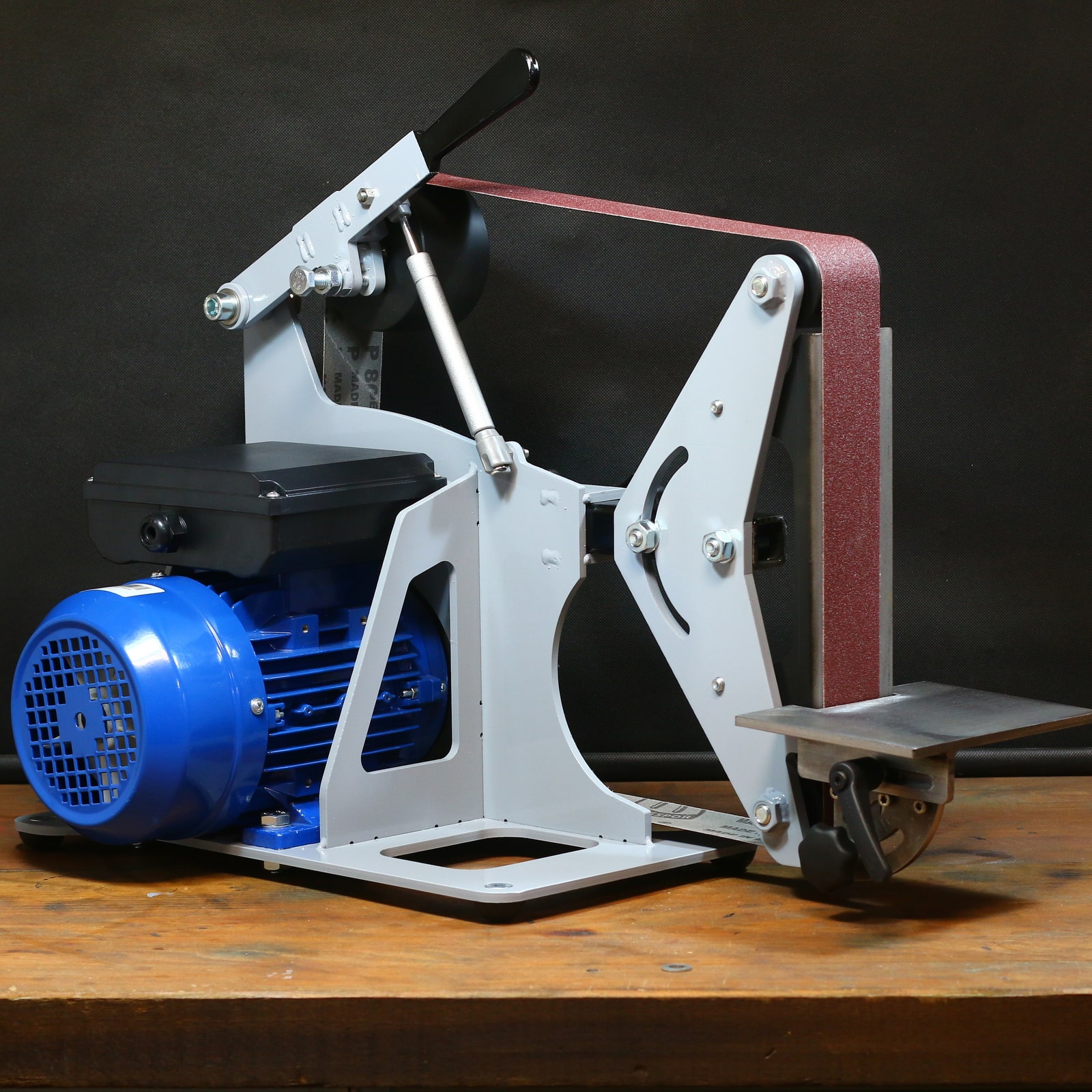

This belt sander is a medium-sized stationary device for the workbench. 1500 × 50mm sanding belts fit on the belt sander. The device is suitable both as a knife grinder for sharpening knives and for general work in metalworking. The grinder mainly consists of 6mm laser cuts. For some parts we use 8mm material. Completely assembled and welded, you get an extremely rigid main body. When assembled, the complete belt sander weighs 25.5 kilos and is secured against slipping by 4 rubber machine feet.

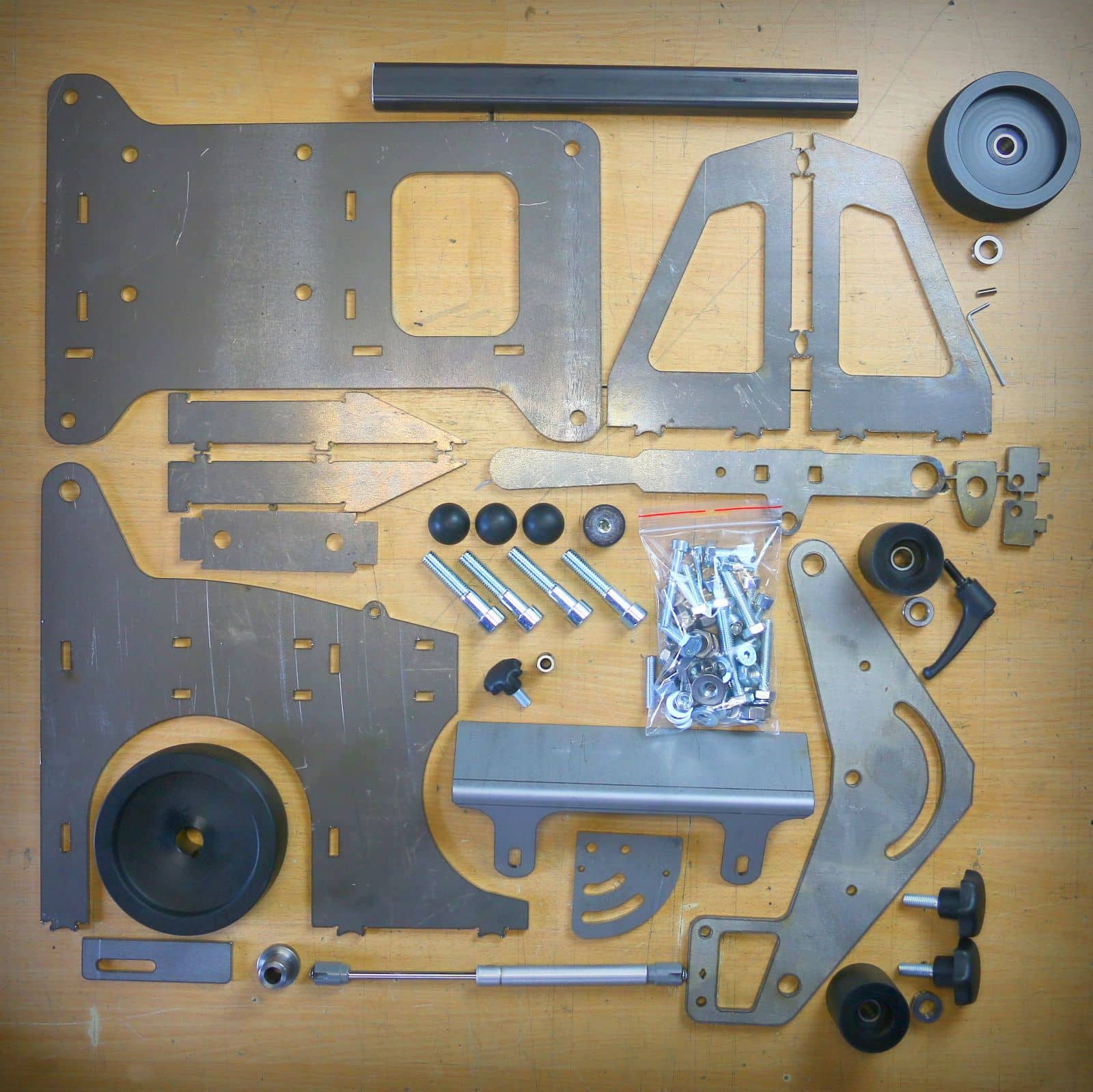

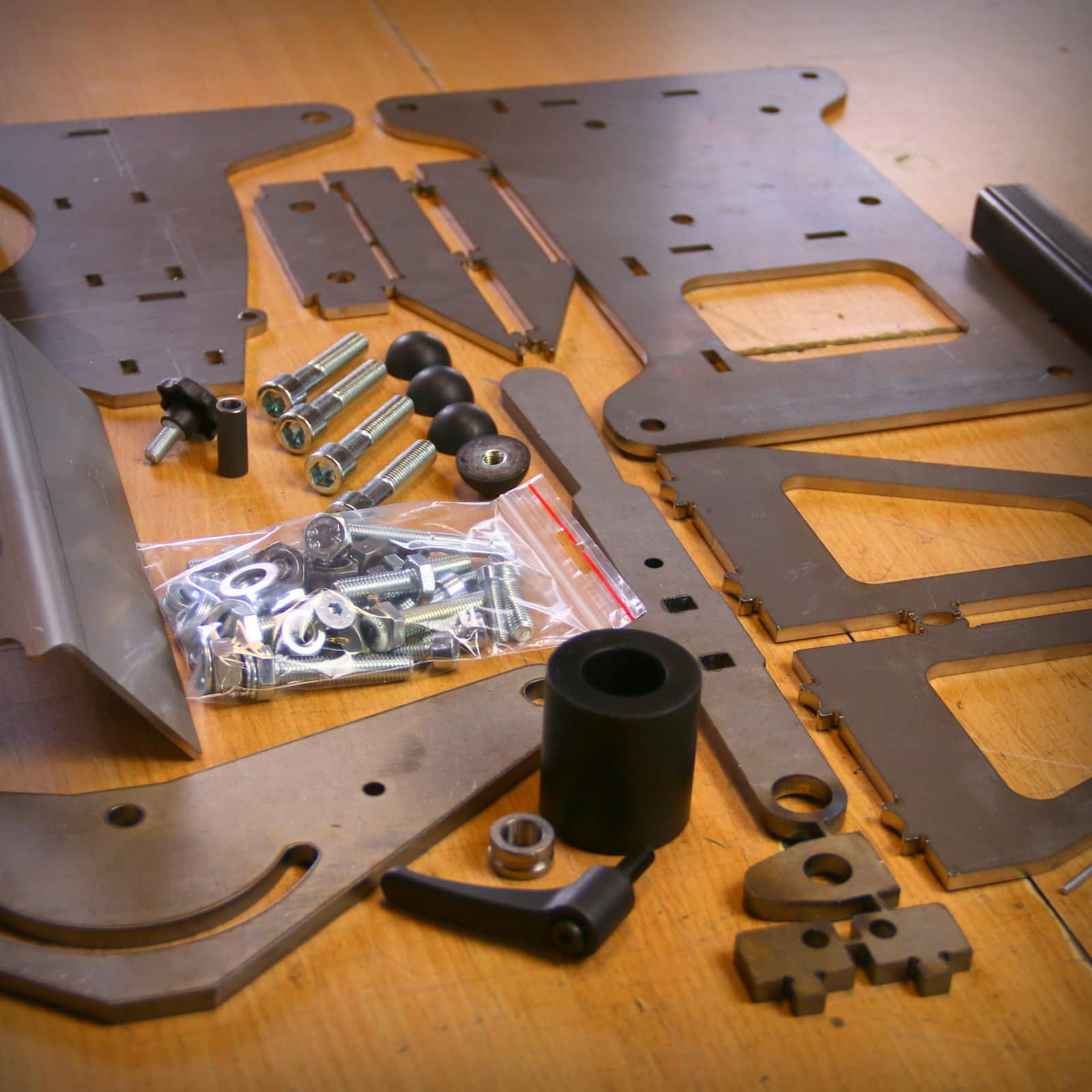

We only offer the device as a kit. A simple inert gas welding machine is required for assembly. If you only have one electrode welding machine, this is not optimal but still possible. You will also need an M8, M6 and M5 thread cutter. All required components (except the electric motor) are included in the kit. You will receive all screws, washers, nuts and adjustment levers from us. The laser parts are pushed into one another via locking holes and then no longer need to be aligned. These locks are welded from the back and thus form a stable basic structure. Here you will find detailed assembly instructions for the BS1500 belt sander.

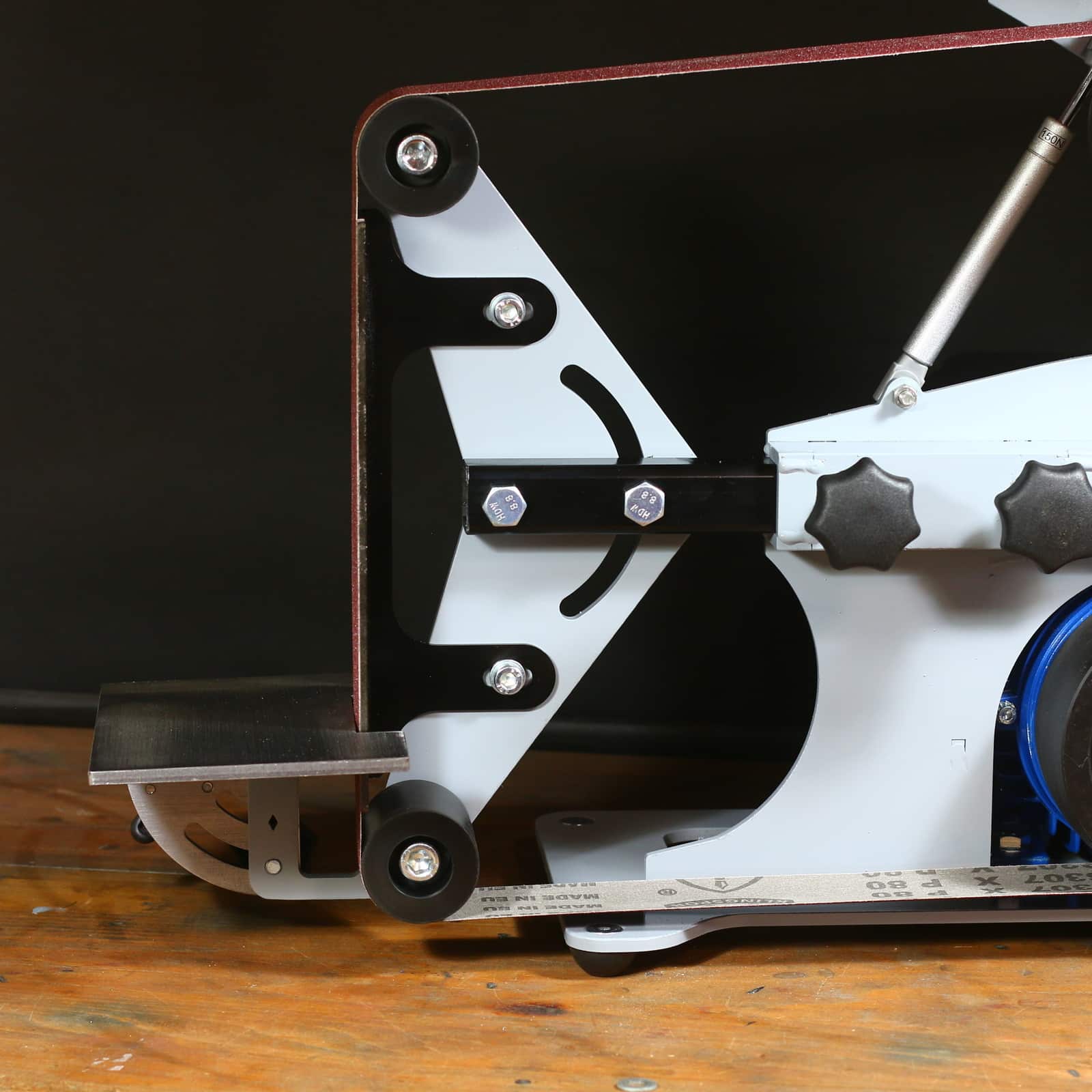

Variant "Kit already welded"

In this variant, all parts are already welded. A welding machine is no longer necessary with this variant. In addition, all holes have already been threaded. All you have to do is drill the holes for the electric motor. As these vary slightly depending on the engine used. All you need to assemble is a set of Allen keys and a set of wrenches.

The motor is also not included in this variant.

The following components are included with the belt sander.

- All laser parts for the machine frame and add-on parts

- 4 high-quality plastic rollers with three bearings

- 3 spacer sleeves for the rollers

- All required screws, nuts and washers

- Clamping levers and star grips

- Gas pressure spring

- Detailed assembly instructions

Technical characteristics of the belt sander

- suitable for sanding belts 1500 × 50 mm

- Weight including 0.75 KW motor 25.5 kilos

- Depth: 59 cm / Width: 40 cm / Height: 51 cm

- Work table can be adjusted up to 45°

- All laser parts have locking holes and do not need to be aligned

The electric motor is not included. You can find the motor at an electric motor dealer here. We tested all motors for suitability for our belt sanders.

1.1kW electric motor 230V, 2800rpm

1.5kW electric motor 230V, 2800rpm

In this video you can see in detail how the kit is assembled.

What is a belt sander?

A belt sander, which you can buy at Bengs Modellbau, for example, is a device that can be used to sand different objects. A motor sets a sanding belt in motion and rotates it at high speed. The way it works can be roughly compared to the principle of a treadmill.

A stationary belt sander also describes a device that remains statically in one place. It is either permanently installed and heavy enough to stay on the work surface without wobbling.

The advantages of a stationary device are that you can sand the desired object at your leisure. While you sometimes have to carry a lot of weight with a mobile device, this is not the case with the stationary version. The device also allows precise grinding work and quick smoothing of rough sawn edges.

How does a belt sander work?

Belt sanders are primarily used when it comes to sanding large areas. For example, it can involve sanding work on materials such as wood, plastic or metal. Metals such as aluminum, which have no iron content, can be cleaned using the device

best grinding. The reason for this is that the chips cause clumping on the sandpaper.In order to sand an object, it must be brought to the belt sander, which you can buy online from Bengs Modellbau, for example. As soon as you switch on the device, it allows material to be removed quickly. Depending on the grain size of the sanding belt, either a coarse or a fine grind is created.

The removal of material or paint is made possible by an endless sanding belt using a stationary device, the kit of which you can buy from Bengs Modellbau, for example. This is wrapped around a drive roller and a deflection roller and is driven by a motor.

What types of belt sanders are there?

Sanders that work with a sanding belt can be divided into two types: the stationary version and the mobile version. At Bengs Modellbau you can buy the kit for a stationary device online.

Both variants differ in their mobility on the one hand and in their functionality on the other. A stationary model always remains at a fixed workplace, while mobile devices can be moved. The stationary grinder also works in such a way that the object to be sanded is brought closer to it. In contrast, the mobile grinder is brought close to the object to be sanded.

A mobile sander is also suitable for smaller jobs as it is usually lighter and more compact to ensure better handling. A stationary grinding device, on the other hand, is ideal for processing large workpieces.

Hersteller

Bengs ModellbauIm Kirchfelde 6

31675 Bückeburg

info@bengs-modellbau.de

Verantwortliche Person

Patrick BengsBengs Modellbau

Im Kirchfelde 6

31675 Bückeburg

info@bengs-modellbau.de

Login