Stirling engine Laura Material Kit

Product information "Stirling engine Laura Material Kit"

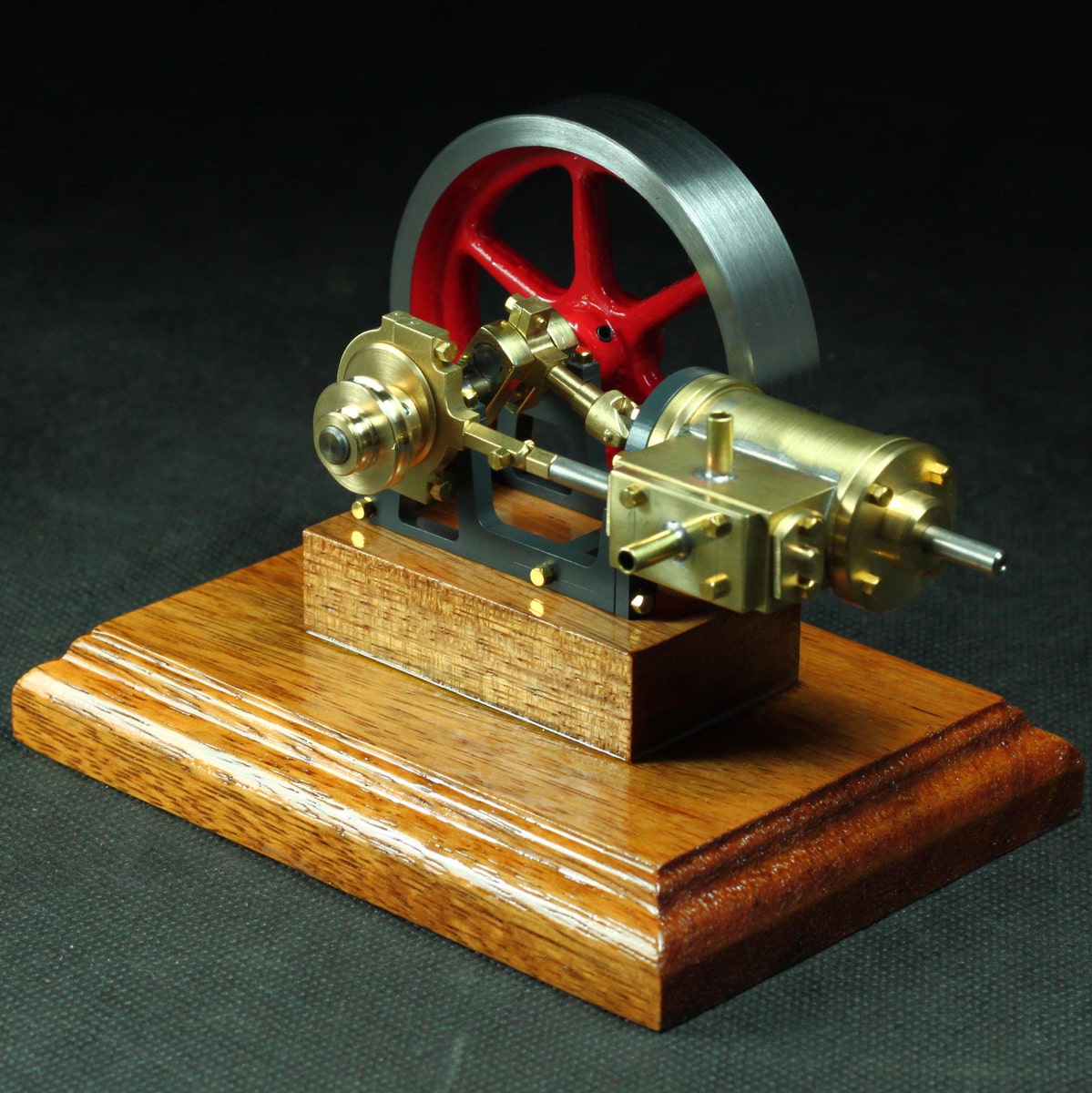

The Stirling engine 'Laura' has parallel cylinders; this type is called gamma type. The engine is a visually very appealing showcase and demonstration model which can be put into operation at any time and anywhere.

The Stirling engine 'Laura' material kit is constructed according to the well-known BENGS model building principle. All milled parts are prepared to such an extent that they only need to be deburred and possibly drilled. The turned parts are unprocessed. The flywheel is pre-turned and milled to such an extent that it can also be finished on a small lathe.

The scope of delivery of the Stirling engine Laura material kit includes:

- Finished milled parts

- Raw material for the turned parts

- very clean 80mm cast flywheel

- Milled oak base plate

- All required screws, nuts, Duran glass tubes, Ball bearings and O-rings

- Construction plan Stirling engine Laura drawings (7 sheets) and construction instructions (3 sheets)

Dimensions Stirling engine Laura:

- Base plate: 140mm x 100mm

- Flywheel: 80mm

- Total height: 105mm

- Working piston: 10mm

- Displacer piston: 13mm

To build the Stirling engine "Laura" material set, you will need a small lathe, a small drill and a gas burner for soldering small parts. Otherwise there are hand tools that should be in every “steam engine workshop” (Tap drill M2, M3, cutting die M2 and M3, reamer 3H7, 6H7, 10H7, files, drill set) are necessary.

Hersteller

Bengs ModellbauIm Kirchfelde 6

31675 Bückeburg

info@bengs-modellbau.de

Verantwortliche Person

Patrick BengsBengs Modellbau

Im Kirchfelde 6

31675 Bückeburg

info@bengs-modellbau.de

Login

SuperCut 2 im Praxistest

Kontakt mit leichten Gegenständen

Wir haben die Messerscheiben seit seit anfang 2022 auf den verschiedensten Rasenmähern getestet und im Einsatz Äste, Stöcker, Fallobst und ähnliche kleine und leichte Gegenstände sind für die SuperCut Messerscheibe kein Problem.

Kontakt mit relativ schweren Gegenständen

Auch schwerere Hindernisse wie dickere Äste, Wurzeln oder Maulwurfshügel stellen für die Messerscheibe kein Problem dar. Moderne Mähroboter erkennen solche Objekte in der Regel automatisch und weichen ihnen selbstständig aus. Sollte es dennoch einmal zu einem Kontakt kommen, bleibt die verbesserte SuperCut 2 Messerscheibe zuverlässig intakt.

Schwereren Gegenständen, Steinen oder Radsteine

Dazu gehören Kollisionen mit großen Hindernissen wie Steinen oder auch das Überfahren von Randsteinen. Bei so massiven Kontakt kann es zu Klingenbrüchen kommen, die Bruchstücke der kingen werden sich jedoch in unmittelbarer Nähe der Unfallstelle befinden. Der Mähroboter verfügt über einen eingebauten Schutz, der eine Überlastung des Motors erkennt und automatisch abschaltet, um größere Schäden zu vermeiden.