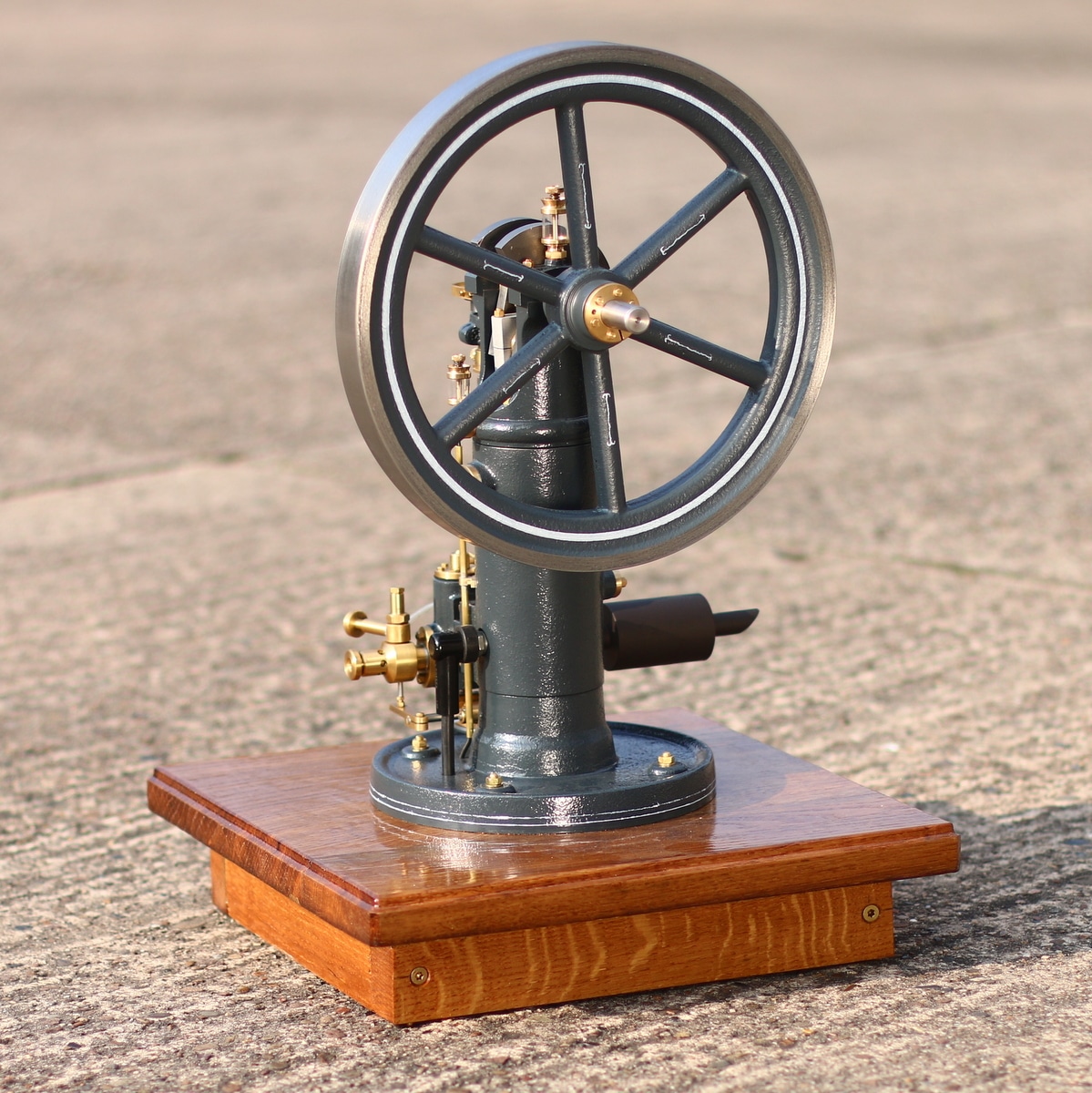

Dürkopp gas engine Diving piston

Product information "Dürkopp gas engine Diving piston"

This casting set was designed on the model of a Dürkopp gas engine. The finished model has an impressive total height of 430mm and many special details. This casting set was previously marketed by Ravensburger steam models. From now on this cast kit is available from us.

To build this casting set, you should already have experience in this model construction area. The flywheel with 280mm diameter requires a large and stable lathe, with a sufficiently large lining and planar disc. You also need a larger milling machine to finish the castings.

This engine is a special construction, the crankshaft lies above and the piston plunges down into the cylinder. This type of motor is called the plunger motor. A cam disk is driven via two bevel gears, through which the inlet and outlet valves are actuated. The valves are not mounted in the cylinder chamber, as are customary today, but are located outside in their own valve housings. In addition, this motor is equipped with a centrifugal governor, which can be used to regulate the amount of the incoming gas.

The Dürkopp immersion piston engine has been designed for operation with gas. It can be operated directly with gas from a propane bottle. Of course, this engine can also be operated with petrol. For this, however, the gas mixer must be exchanged for a carburettor. Our experience has shown that this engine runs with gas much smoother and more beautiful. We recommend operating with gas.

Required tools and machines

For the construction of the combustor, an extensive workshop, with a large lathing machine and a medium-sized stable milling machine is needed. The lathe should be able to machine a flywheel with an outer diameter of 300 mm. For machining the castings on the lathe, a planar disk should also be present. In addition, a stator drilling machine and a torch for soldering larger parts will be available. Furthermore, hand tools (taps M2, M3, M4, M6x0,75, M10x1 / cutter M2, M3, M4, M8, M6x0,75, M10x1 / reamers 3H7, 4H7, 5H7, 6H7,15H7 files, drill set) are necessary , To solder the ignition, a soldering iron is required for this model.

We have prepared for you an extensive construction report of the Dürkopp gas engine. The building report is subdivided into subassemblies and is designed to assist you in the manufacture of the engine. Furthermore, you can see in the building report whether your machine park is of sufficient size.

Baubericht Dürkopp Tauchkolben Gasmotor

Dimensions of the finished engine:

- Height: 430mm

- Thrust Gusssockel (cylinder head): 195mm

- Diameter of flywheel: 290mm

- Diameter of piston: 40mm

- Piston stroke: 60mm

- Weight with wooden base: 20kg

You have the choice between 4 different variants.

You have the choice between different sets of gasmotor Dürkopp. With Set 2 you get the drawing, the cast parts and some special parts. If you order Set 4 you will get all the components and screws needed to build the engine. With Set 4 everything from the piston to the power supply is there and you do not have to leave the hobby workshop until the completion of the engine.

Dürkopp vertical Gas engine Set 1 / Construction Plan

- Construction plan Dürkopp Gasmotor consisting of drawings (3 sheets DIN A3, 22 sheets DIN A4

Dürkopp vertical Gas engine Set 2 / Construction Plan, cast parts

- Construction plan Dürkopp Gasmotor consisting of drawings (3 sheets DIN A3, 22 sheets DIN A4)

- Cast iron (1x flywheel 280mm, 1x cylinder head with foot, 1x cylinder jacket, 1x crankshaft bearing block, 2x bearing cover, 2x valve housing,)

- Special parts 40mm cylinder tube, piston rings, bevel gears

Dürkopp vertical Gas engine Set 3 / Construction Plan, cast parts, screws and ignition

- Construction plan Dürkopp Gasmotor consisting of drawings (3 sheets DIN A3, 22 sheets DIN A4)

- Cast iron (1x flywheel 280mm, 1x cylinder head with foot, 1x cylinder jacket, 1x crankshaft bearing block, 2x bearing cover, 2x valve housing)

- Special parts Cylinder tube, piston rings, bevel gears

- Screws, springs, seals and all parts for ignition

Dürkopp vertical Gas engine Set 4 / Construction Plan, cast parts, screws and ignition, round material

- Construction plan Dürkopp Gasmotor consisting of drawings (3 sheets DIN A3, 22 sheets DIN A4)

- Cast iron (1x flywheel 280mm, 1x cylinder head with foot, 1x cylinder jacket, 1x crankshaft bearing block, 2x bearing cover, 2x valve housing)

- Special parts Cylinder tube, piston rings, bevel gears

- Screws, springs, seals and all parts for ignition

- Brass, aluminum, gunmetal and silver steel for all turning parts

Hersteller

Bengs ModellbauIm Kirchfelde 6

31675 Bückeburg

info@bengs-modellbau.de

Verantwortliche Person

Patrick BengsBengs Modellbau

Im Kirchfelde 6

31675 Bückeburg

info@bengs-modellbau.de

Login