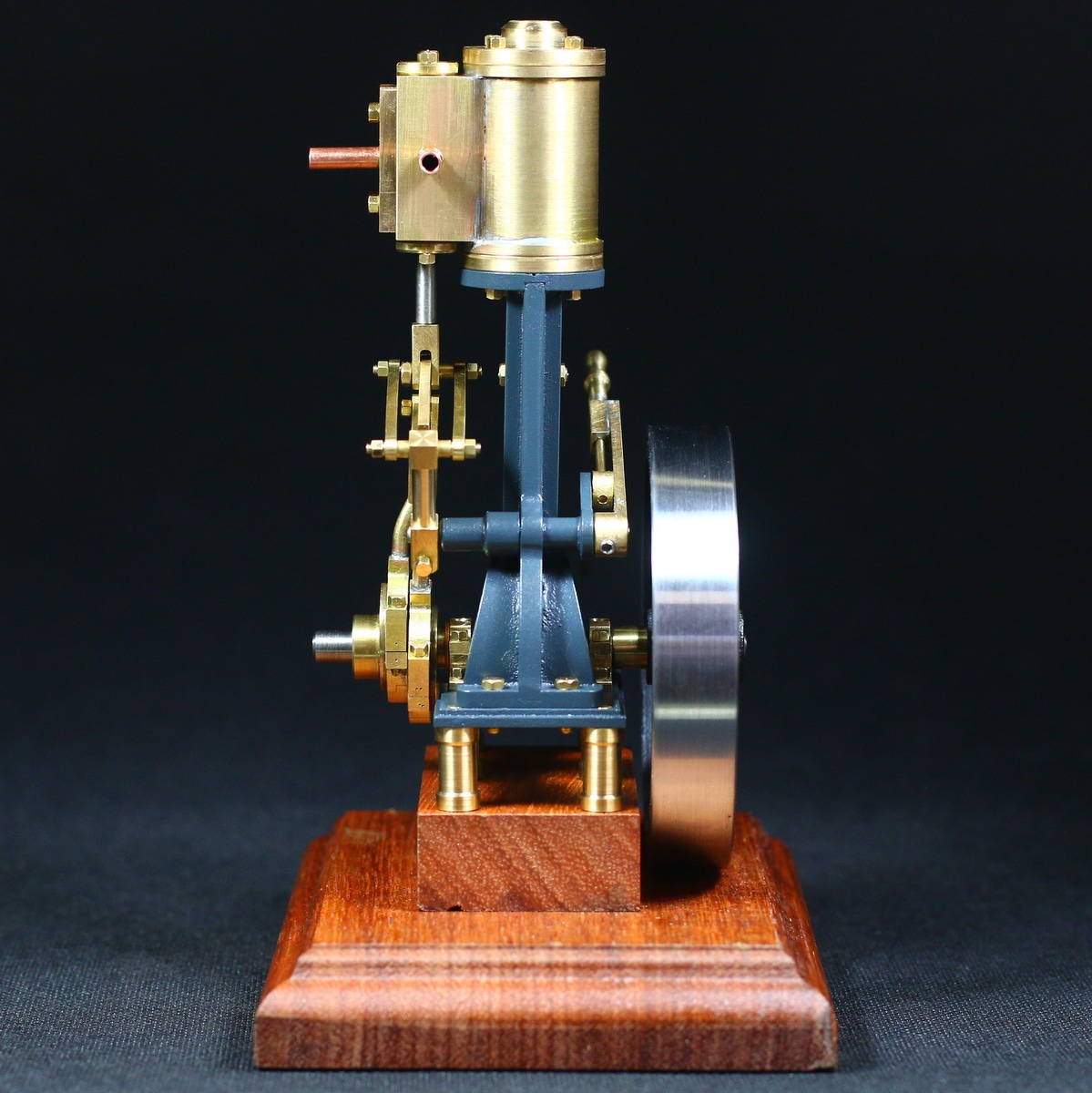

Vertical steam engine Leni with reversal

Product information "Vertical steam engine Leni with reversal"

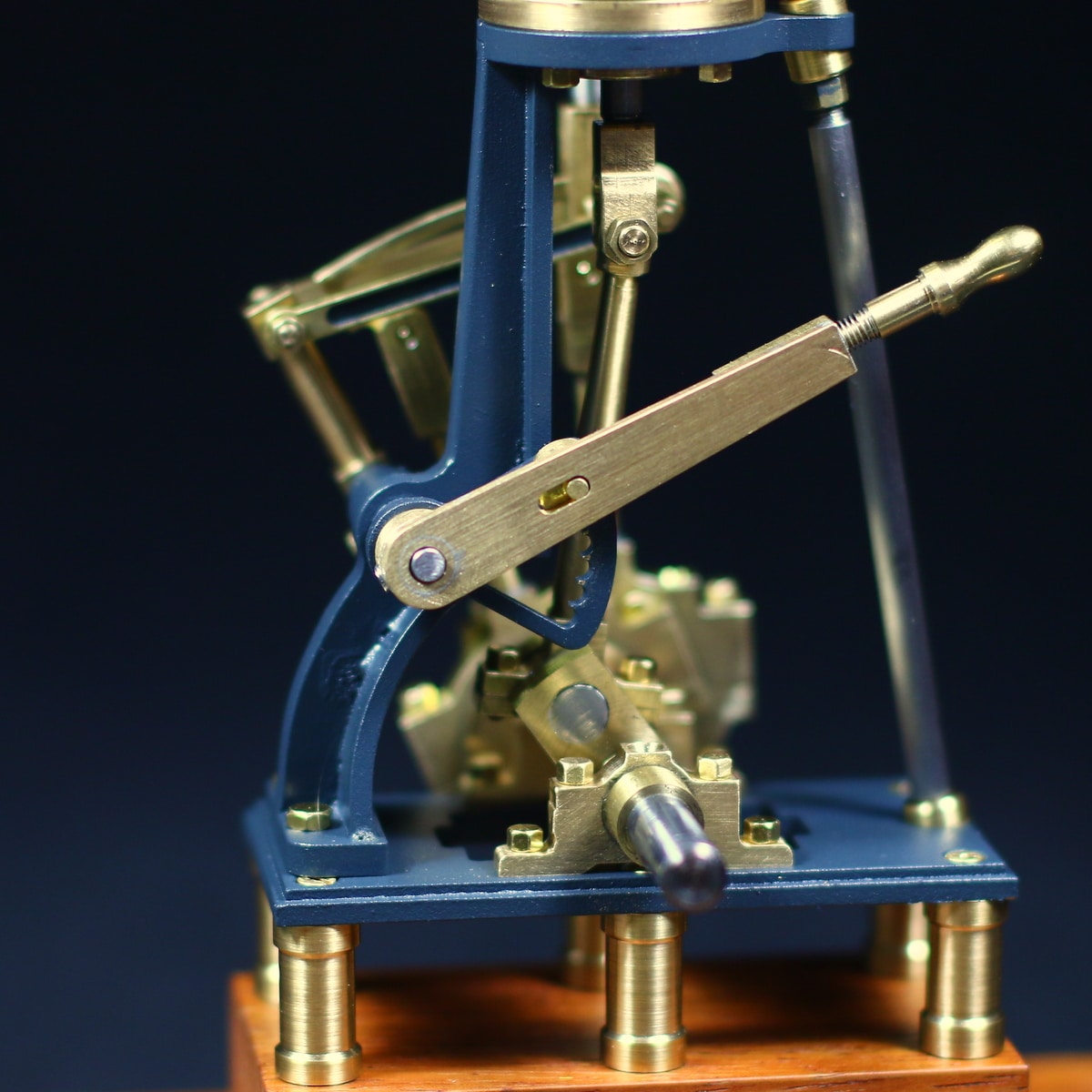

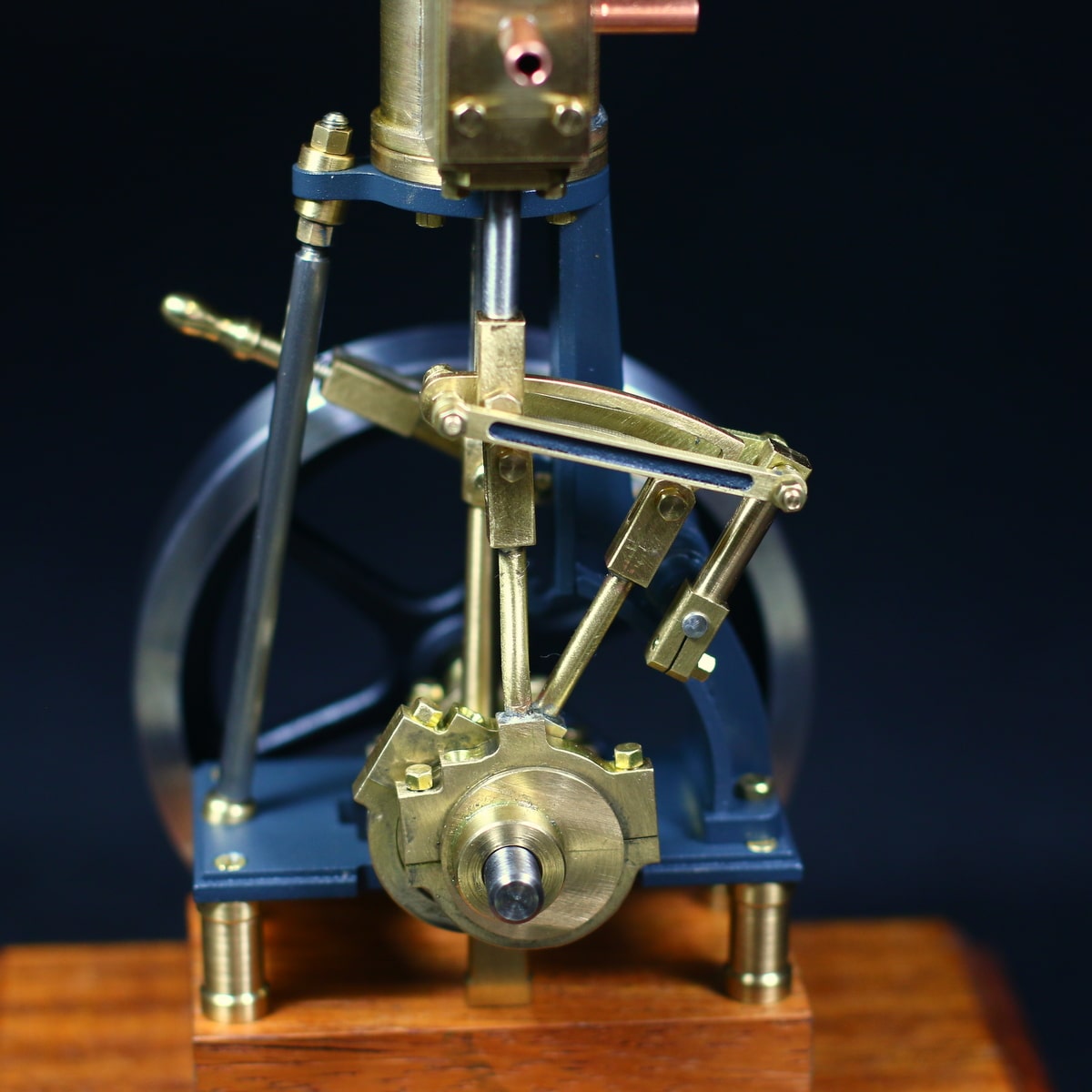

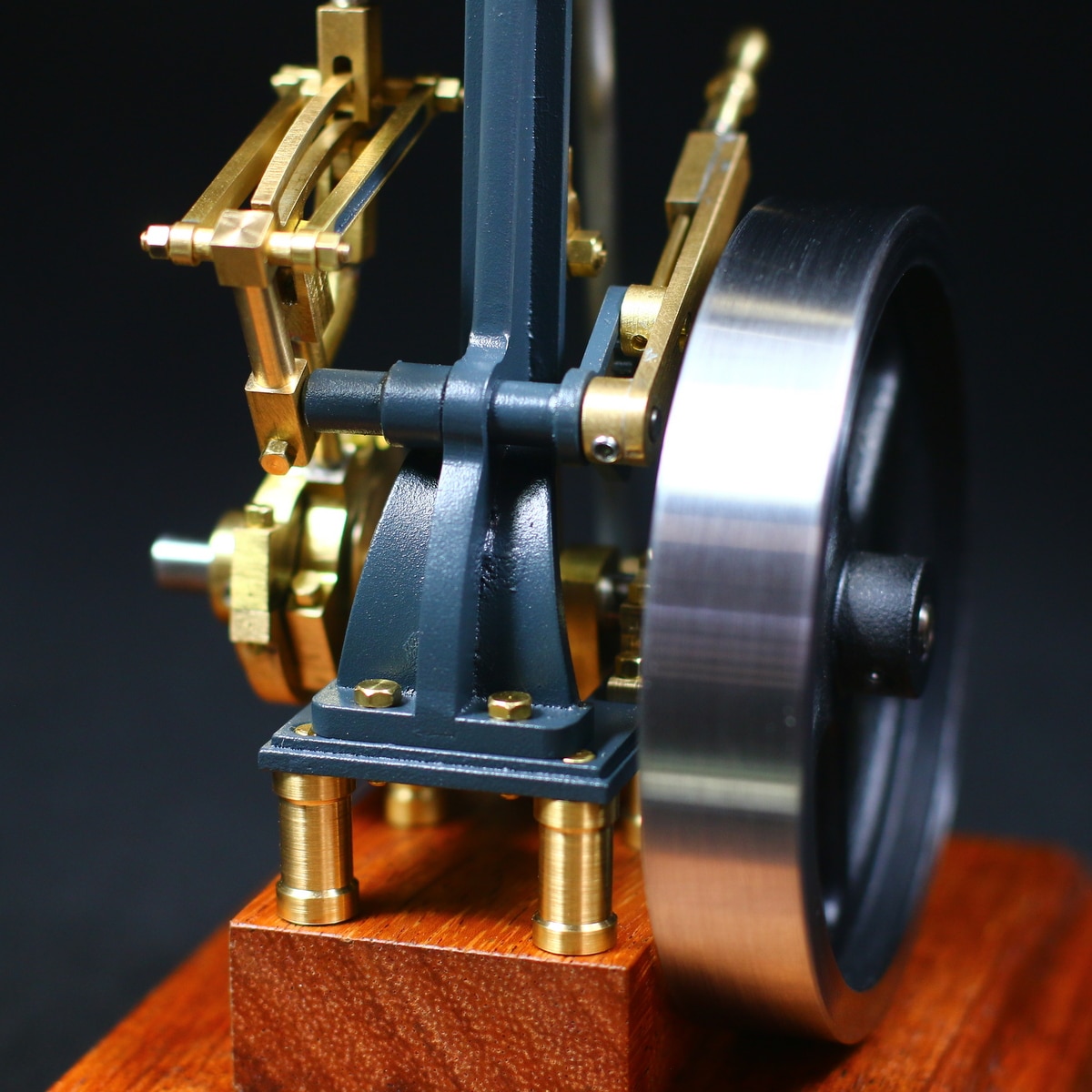

The Leni steam engine is a model of a standing steam engine with Stephenson reversal. With its 80 mm flywheel and a total height including the base plate of 185 mm, the model is a good size so that it can also be manufactured in smaller model workshops. This type of steam engine was built from around 1840 until the 20th century. This standing design often found its place in small craft businesses where it powered various tools or generators. The direction of rotation of the steam engine can be changed at any time using the Stephenson reversal.

The construction plan and instructions for this standing steam engine are very extensive, detailed and easy to understand. This makes the kit not only suitable for model building professionals but also for newcomers to technical model building. The construction instructions go into the production of each component. In addition to the detailed printed instructions, you will also find a comprehensive construction report of the Leni steam engine in our Bengs model building magazine. For the model builder who has always wanted to build a steam engine with Stephenson reversing, the standing steam engine “Leni” is a good choice. But even advanced model makers will enjoy this visually beautiful standing steam engine model. The machine is suitable for both the display case and as the centerpiece of a model steam system.

The Leni model steam engine is mainly made of brass, the piston is made of gunmetal. Piston rods and slides are made of stainless steel. The flywheel is a very precise cast steel where the outer diameter only needs to be turned slightly once.

Included in the Leni steam engine material kit

- Milled oak base plate

- Finished milled parts

- Brass, bronze, stainless steel and silver steel raw material for the turned parts

- Cast steel flywheel 80mm

- All required screws, nuts and grub screws

- Construction plan model steam engine "Leni" drawings (14 sheets) and construction instructions (8 sheets)

Dimensions of the steam engine Lenni

- Height with base plate: 185mm

- Length with base plate: 140mm

- Width with base plate: 100mm

- Piston diameter: 15mm

- Piston stroke: 18mm

- Flywheel D.: 80mm

- Weight: 900g.

Some tools are required to build the “Leni” steam engine material kit. A small lathe and a small drill are particularly important. A gas burner is required for soft soldering, for example the small gas soldering tool CFH Diamant M50 is suitable. M2 and M3 taps and M2 and M3 cutting dies are also needed. You also need reamers 3H7, 4H7, 6H7, screw glue, files and a drill set. p>

A detailed Construction report on the steam engine “Leni” can be found in our Bengs model building magazine. On the page you will find many pictures and texts with details and suggestions on how the components of the steam engine can be manufactured.

Hersteller

Bengs ModellbauIm Kirchfelde 6

31675 Bückeburg

info@bengs-modellbau.de

Verantwortliche Person

Patrick BengsBengs Modellbau

Im Kirchfelde 6

31675 Bückeburg

info@bengs-modellbau.de

Login