Vertical gas engine Otto V casting set

Product information "Vertical gas engine Otto V casting set"

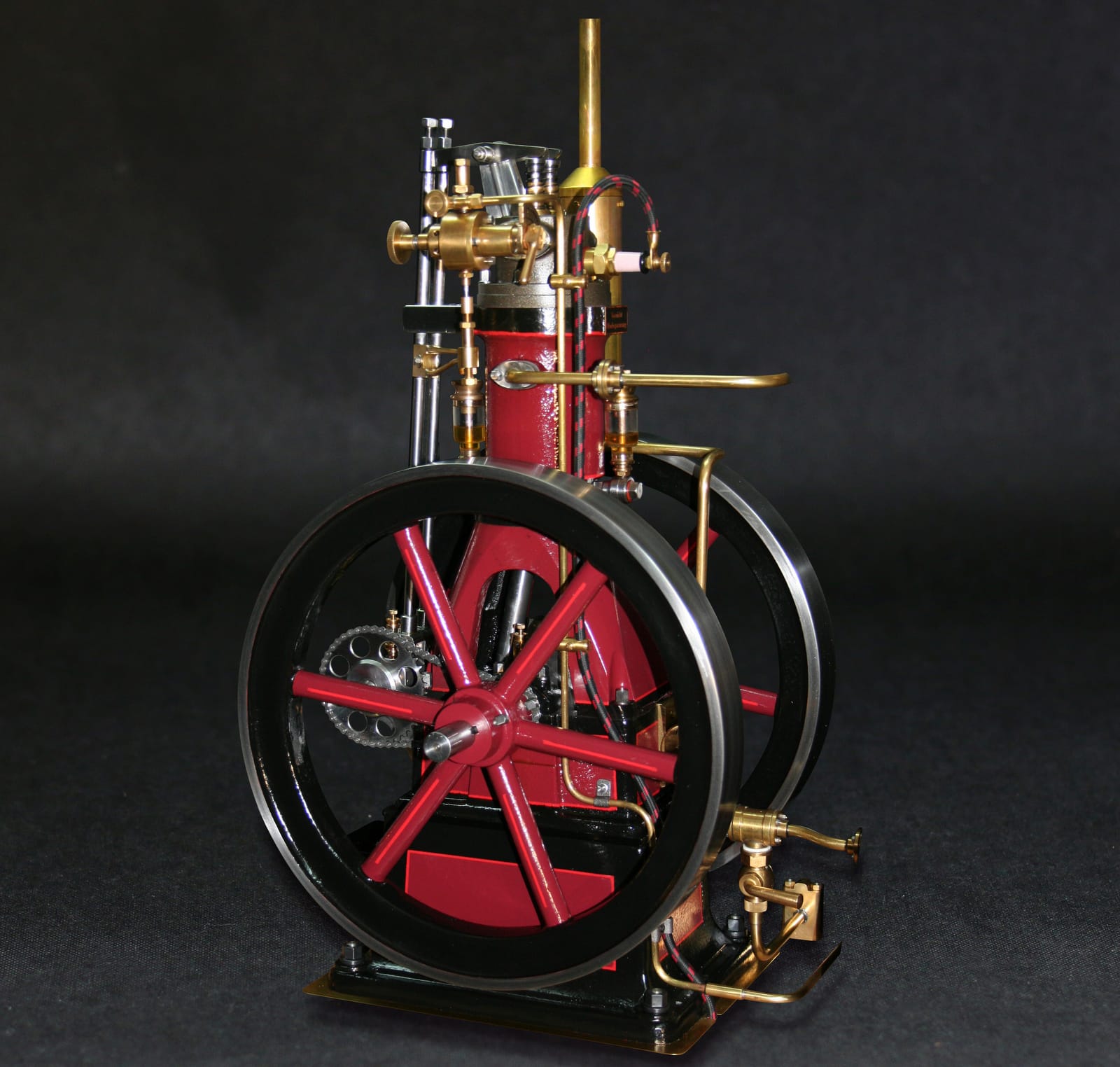

With this set of cast parts you have the opportunity to build a prototypical model engine of the type that was used as a large engine at the beginning of the last century (e.g. to generate electricity in factories). The large piston stroke and large bore enable a speed of less than 130 rpm. The quiet and slow running of the engine arouses true enthusiasm among connoisseurs. The valves are controlled via a timing chain that drives the camshaft. The dimensions of the gas engine are already clear from the weight. It weighs around 50 kg. With this engine, a true-to-life power plant can be built to generate electricity.

This set of castings was previously sold by the Ravensburger Dampfmodelle company. This casting set, drawing and spare parts are now available from us in the Bengs Modellbau online shop. We supply most of the special parts needed to build the engine. You can use the components we offer as ignition. Here you can find the parts for the ignition (Ignition coil , Interrupter, Kondensator, Spark plug).

The castings are molded and cast by hand in a small foundry in Germany. Most of the castings are made of GG25, the cylinder head is delivered in cast aluminum. Due to the large dimensions of this engine, you should have an excellently equipped workshop with a large lathe and a large milling machine.

Here you will find a detailed construction report from the Otto gas engine vertical in our magazine.

Technical data Vertical gas engine Otto V

- Power: approx. 0.7/0.5 HP/kW

- Speed speed: approx. 130 rpm

- Bore/stroke: 50/80 mm

- Displacement: 150 cc

- System: Otto

- Ignition: battery ignition

- Fuel: Gas

- Lubrication: Drip oiler

- Flywheel Ø approx. 350 mm

- Flywheel width: approx. 42 mm

- Shaft width: approx. 300 mm

- Motor height: approx. 600 mm

- Flywheel: approx. 20 kg weight

Scope of delivery: cast parts

- Base / GG25

- Base / GG25

- Cylinder / GG25

- Bearing block / GG25

- Bearing cap / GG25

- 2x flywheel / GG25

- Cylinder head / cast aluminum

Includes small parts

- Drawing

- Sprocket 1 / steel

- Sprocket 2 / steel

- Liner for cylinder

- 2x piston rings

- 2x valve springs

- Steel roller chain

- Chain lock

Hersteller

Bengs ModellbauIm Kirchfelde 6

31675 Bückeburg

info@bengs-modellbau.de

Verantwortliche Person

Patrick BengsBengs Modellbau

Im Kirchfelde 6

31675 Bückeburg

info@bengs-modellbau.de

Login